- Home

- Products information

- Super dehydrator[Centrifugal dehydrator](SDK)

Super dehydrator[Centrifugal dehydrator]

Continuous dehydrator, screw discharge type | SDK SERIES

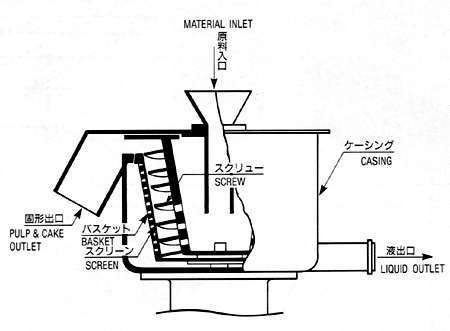

Super dehydrator, SDK series, the vertical continuous dehydrator, is designed by our longstanding manufacturing technique & skill. Simple structure, just needs centrifugal force to do the work. Needless of redundant conventional works such as compressing, kneading & etc. Supplied solutions will dehydrate continuously with auto-discharge of dregs.

Application

-

WASHING & DEHYDRATING

- Cabbage, onion, carrot, bamboo sprout, mushroom, seaweeds, etc.

- Beverage, grain, rice, beans and etc.

- Chemical industry products.

Figure

Specification

| Type | Centrifugal effect[Maximum] (G) |

Rotation speed[Maximum] (r.p.m) |

Power (KW) |

Capacity (m3/H) |

Dimensions (L×W×H【m】) |

Weight (kg) |

|---|---|---|---|---|---|---|

| SDK-360VS | 500 | 1,600 | 3.7 | 0.1~0.5 | 1,100×600×1,500 | 500 |

| SDK-460VS | 500 | 1,400 | 5.5 | 0.4~1.0 | 1,300×800×1,700 | 700 |

| SDK-600VS | 500 | 1,200 | 7.5 | 0.8~1.5 | 1,500×950×1,800 | 1,000 |

※Please note that all specifications are subject to change without notice due to product improvements.

Option [Centrifugal juicer]

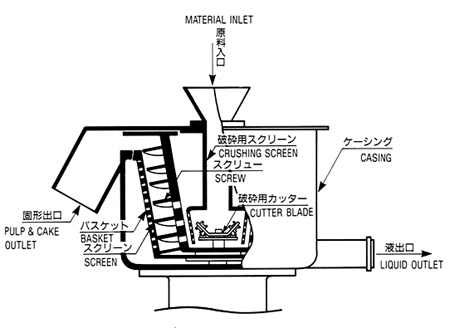

There are two types of juicer conventionally known to get juice from fruits or vegetables: one is to directly compress the fruits or vegetables; another is to finely crush them first before the compression. Therefore, they have to be separately made into two machines. In Saito Separator, we develop a compact and unique juicer which combines both continuous dehydrator and shredding device.

After the materials are input by hopper, they are crushed by shedding cutter and pushed against the inner surface of basket by centrifugal force. Liquid is shaken out from the screen holes, collected in casing, and output from juice exit. Pomace left in the basket is discharged from pomace exit by screw conveyor.

Application

- Fruit, orange, Kabosu, Sudachi, radish, apple, vegetable, guava, tomato, grape, etc.

Special Features

- Shredding and juicing are completed by one instrument. Pomace and juice are completely separated and extracted.

- It handles every task in the most efficient way to meet the intended use.

- It is compact and low cost because of its mechanism of using centrifugal force.

Figure

Specification

| Type | Centrifugal effect[Maximum] (G) |

Rotation speed[Maximum] (r.p.m) |

Power (KW) |

Capacity (m3/H) |

Dimensions (L×W×H【m】) |

Weight (kg) |

|---|---|---|---|---|---|---|

| SDK-360VS | 500 | 2,200 | 3.7 | 0.1~0.5 | 1,100×600×1,500 | 500 |

| SDK-460VS | 500 | 1,970 | 5.5 | 0.4~1.0 | 1,300×800×1,700 | 700 |

| SDK-600VS | 500 | 1,700 | 7.5 | 0.8~1.5 | 1,500×950×1,800 | 1,000 |

※Please note that all specifications are subject to change without notice due to product improvements.

![Super dehydrator[Centrifugal dehydrator]](img/img_sdk_main_01.jpg)

![Super dehydrator[Centrifugal dehydrator]](img/img_sdk_main_02.jpg)